If you have arrived here after reading, and hopefully enjoying the previous posts, I would like to say thank you.

The story began many, many years ago, while walking in concrete slurry and mud, I thought there had to be a safer, cleaner way to deal with the concrete washout waste after washing a concrete pump.

So, I took to paper and came up with my concept.

Just like the concreters have moved on from pushing wheelbarrows, PumperDump has grown to offer more than just a bin service.

When using PumperDump we assist you to:

- Avoid using plastic for washout trays

- Avoid the use of your onsite plant equipment

- Save your manual labour time and cost to clean up messes

- Eliminate extra tip fees

- Better manage any water runoff and possible pollution infringements

- Give recyclers an uncontaminated product to recycle

- Reduce unnecessary carbon emissions

- Introduce sustainable practices while dealing with concrete waste

- Improve onsite safety

- One price no hidden costs

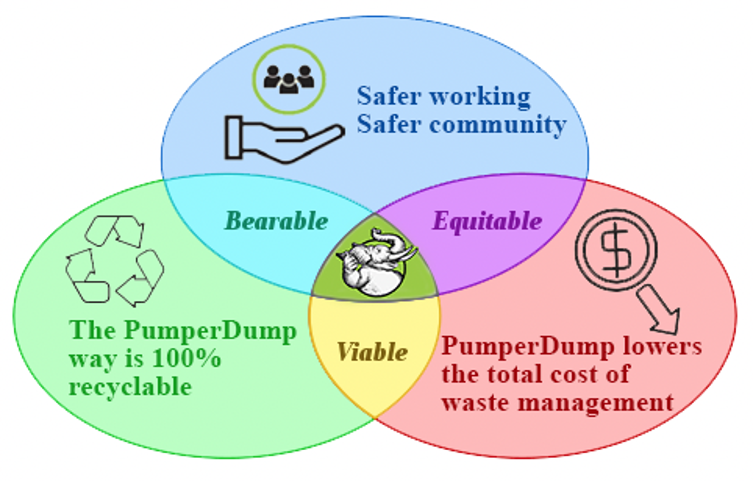

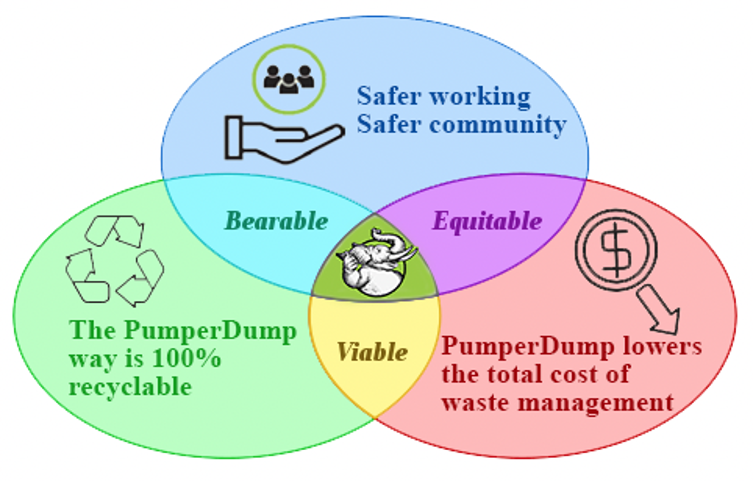

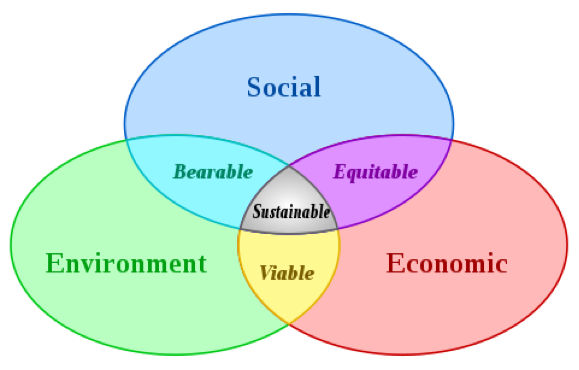

Just like the sustainability Venn diagram shows, sustainability covers many areas and we have grown and innovated through constant dialog with builders, assisting them to solve their problems, and in doing that, we have also been able to assist them with their sustainability goals.

It looks simple and is simple, but what this bin can offer is a lot more.

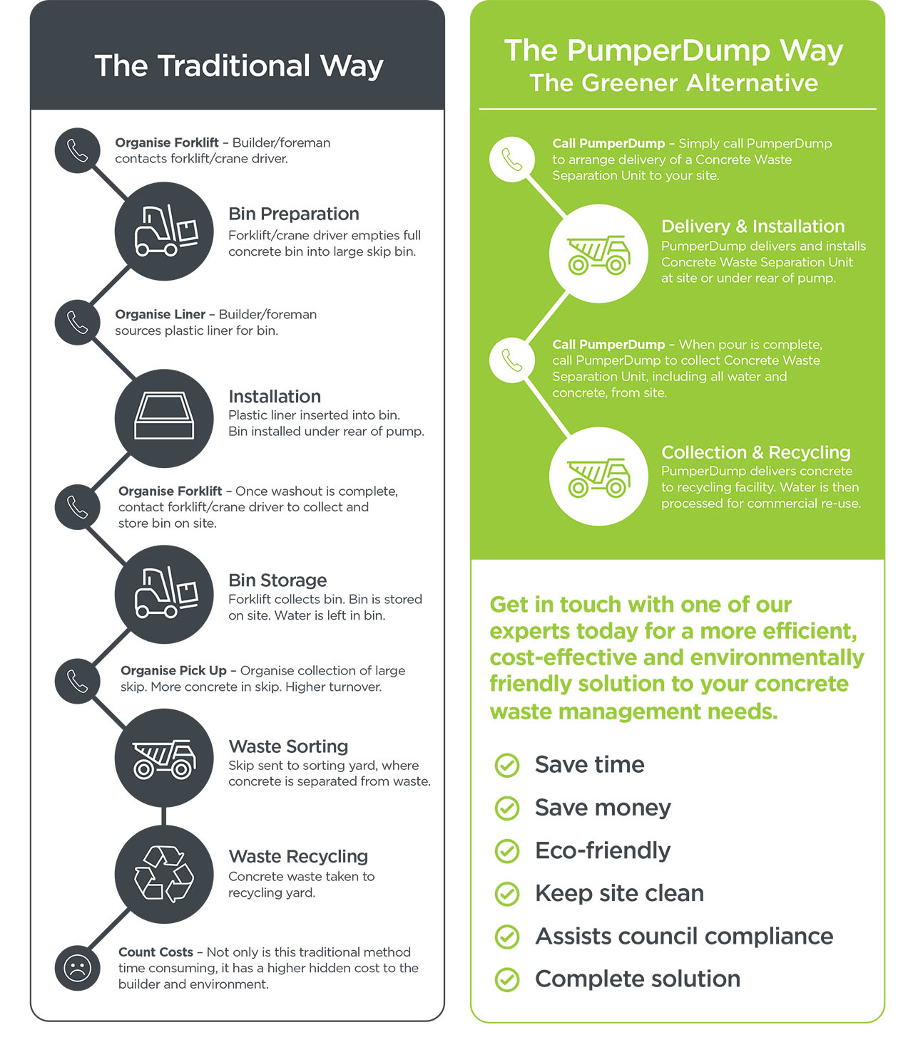

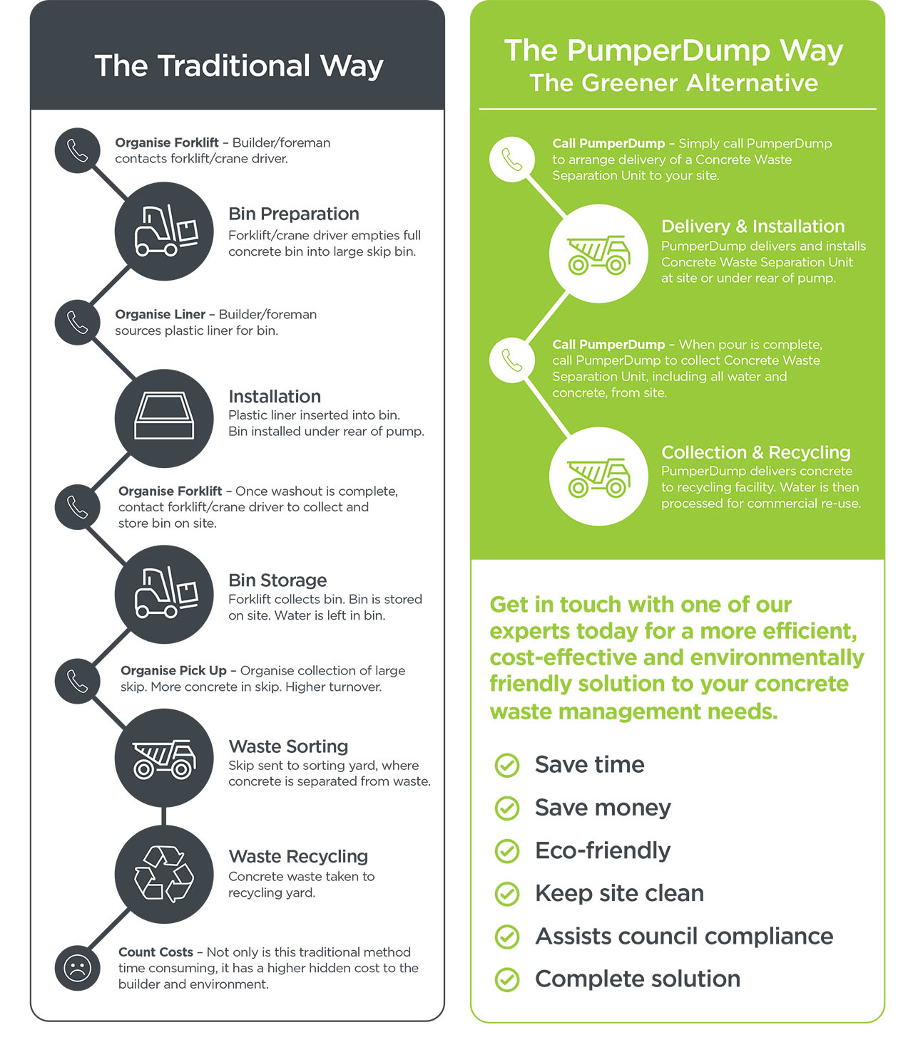

This following chart compares the process and time builders take to deal with the washout tray onsite compared to using PumperDump. It shows the extra plant machinery handling and truck movements taken when done the traditional way.

PumperDump’s Concrete Waste Separation Unit, (CWSU) as we call it, has a 1m3 volume, with an inner tray to capture the concrete and an outer tray to store the wash water to be processed and recycled. PumperDump trays have a larger volume than the standard tray and yes, they can also be overfilled, but the outer tray gives room for the water and a better indication of when the limit will be reached.

We give builders back their skip bin volume for real rubbish, keeping any overweight charges to a minimum and help them mitigate the risk of fines with no more water running out of transported skips.

We don’t tie up onsite plant leaving them to be better utilised for onsite operations.

PumperDump’s no plastic policy delivers the recycler an uncontaminated concrete waste. Instead of plastic, we use our specially formulated water-based concrete release agent on all our bins.

We offer certificates on the concrete and water collected and recycled and the volume of plastic diverted from landfill.

Even when construction has commenced, some builders and concreters are reluctant to use PumperDump, believing it’s an extra cost without seeing the many hidden costs already associated with the cleaning and disposal of concrete waste.

My story goes, from walking through concrete slurry and mud after washing a concrete pump, to starting and growing PumperDump, to now offering a range of services that will help you to a safer more sustainable concrete pumping 21th century.

Want to know more, then get in touch

#PumperDumpSolution #Construction #ConstructionIndustry #ConcreteRecycling #ContructionWaste #ConcreteSolutions #ConcreteManagement #ConcretePump #ConcreteWashout #ConcreteWasteManagement #C&DWaste #CircularEconomy #GreenBuilding #Pollution #NSW #NSWGovernment #Sustainability #Sydney #SydneyConstruction

Is concrete washout really that bad for the environment?

It’s reasonable to wonder if all the racket made over concrete washout is all that justified. After all, concrete structures can be found far and wide, and they don’t seem to be harming anything. Is this perhaps just a case of the NSW Environment Protection Authority (EPA) being overly-cautious and simply extending its reach beyond where it belongs?

In short – NO. Concrete washout really is that harmful to the environment. Sure, concrete structures are everywhere. Once concrete dries, it becomes a stock-still substance that no longer poses a threat. Before that, the concrete mixture – and the water that was used in it (not excluding the water that was used to clean off the tools and trucks) – is corrosive. This material contains, grout, plaster, cement, mortar, stucco and other materials that contain harmful chemicals. The danger arises from these materials leaking into local water sources. As previously mentioned, concrete washout water has a toxicity level greater than ammonia and near the same pH level as chlorine bleach. It’s obvious as to why PumperDump tries so hard to prevent these substances from reaching our local water systems.

What can we do about concrete washout?

So now that it is evident that concrete washout is permissibly harmful to ecosystems, including our waterways. We’ve established that the regulations and precautions implemented by the NSW Environment Protection Authority (EPA) are not mere overreactions. What now? What can be done about concrete washout?

Good news, there are several ways to approach concrete washout. An approach to concrete washout that used to be very popular was washout pits and washout bags. We’ve discussed before why these “solutions” are a thing of the past. There are many risks – both environmentally and financially – that come from choosing either washout pits or washout bags. We do not recommend it. You simply do not want to make use of inefficient washout systems. Doing so risks:

Is concrete washout really that bad for the environment?

It’s reasonable to wonder if all the racket made over concrete washout is all that justified. After all, concrete structures can be found far and wide, and they don’t seem to be harming anything. Is this perhaps just a case of the NSW Environment Protection Authority (EPA) being overly-cautious and simply extending its reach beyond where it belongs?

In short – NO. Concrete washout really is that harmful to the environment. Sure, concrete structures are everywhere. Once concrete dries, it becomes a stock-still substance that no longer poses a threat. Before that, the concrete mixture – and the water that was used in it (not excluding the water that was used to clean off the tools and trucks) – is corrosive. This material contains, grout, plaster, cement, mortar, stucco and other materials that contain harmful chemicals. The danger arises from these materials leaking into local water sources. As previously mentioned, concrete washout water has a toxicity level greater than ammonia and near the same pH level as chlorine bleach. It’s obvious as to why PumperDump tries so hard to prevent these substances from reaching our local water systems.

What can we do about concrete washout?

So now that it is evident that concrete washout is permissibly harmful to ecosystems, including our waterways. We’ve established that the regulations and precautions implemented by the NSW Environment Protection Authority (EPA) are not mere overreactions. What now? What can be done about concrete washout?

Good news, there are several ways to approach concrete washout. An approach to concrete washout that used to be very popular was washout pits and washout bags. We’ve discussed before why these “solutions” are a thing of the past. There are many risks – both environmentally and financially – that come from choosing either washout pits or washout bags. We do not recommend it. You simply do not want to make use of inefficient washout systems. Doing so risks:

What’s the responsible option

PumperDump offers alternatives to the inefficient washout systems. We have brought together innovative technology, patented concrete washout separation units and blowback units, a dedication to efficient and quality services, and a passion for ethical environmental practices to bring the industry the best concrete washout solutions.

All in all, we understand the importance of needing to tackle construction projects affordably and efficiently, whilst also maintaining ethical environment practices.

PumperDump is the responsible choice. We are your solution to washout pollution. Get in contact with one of our concrete washout solution specialists at info@pumperdump.com.au or by using the PumperDump App (App Store) (Google Play)

What’s the responsible option

PumperDump offers alternatives to the inefficient washout systems. We have brought together innovative technology, patented concrete washout separation units and blowback units, a dedication to efficient and quality services, and a passion for ethical environmental practices to bring the industry the best concrete washout solutions.

All in all, we understand the importance of needing to tackle construction projects affordably and efficiently, whilst also maintaining ethical environment practices.

PumperDump is the responsible choice. We are your solution to washout pollution. Get in contact with one of our concrete washout solution specialists at info@pumperdump.com.au or by using the PumperDump App (App Store) (Google Play)

While I have been told of machines with cracks appearing on the boom or the rotator being damaged, the photo below shows damage to a manitou tyne from lifting overweight bins and constant banging. The new attachment sits in the distance. It was a $4k fix and this is on a tier 1 builder’s site!

While I have been told of machines with cracks appearing on the boom or the rotator being damaged, the photo below shows damage to a manitou tyne from lifting overweight bins and constant banging. The new attachment sits in the distance. It was a $4k fix and this is on a tier 1 builder’s site!